ModuLase aims to develop, validate & demonstrate a rapidly re-configurable laser process head that:

- Is capable of welding, cladding and cutting, through the use of three modular end-effectors

- Includes intelligent sensor technologies for in-process monitoring

- Is linked to an intelligent system, in order to achieve adaptive process control, quality assurance, and semi-automated process parameter configuration.

State-of-the-art fibre-delivered laser sources are an industrially accepted tool for performing a range of materials processing applications. Despite the unrivalled capability of fibre-delivered laser sources to perform a wide range of processes, their potential flexibility is limited by the need to change the processing head for these processes to be performed. The majority of industrial laser systems are employed to perform low-variety and high-volume manufacturing operations. However, current manufacturing trends (such as increased automation, individualisation and next-shoring) are driving the need to develop manufacturing systems which are capable of performing a higher variety of manufacturing operations.

The specific objectives of the ModuLase project were to develop a re-configurable highly flexible processing head system, capable of covering welding, cladding and cutting, compatible with existing and future fibre-delivered laser process systems. ‘Plug and play’ solutions for automated changing of end-effectors in less than 1 minute have been developed as part of the project.

The ModuLase process head system also includes intelligent sensor technologies for quality assurance and semi-automated process parameter configuration.

The ModuLase system has been validated within an industrial environment.

The potential flexibility of fibre-delivered laser sources has been demonstrated, addressing the following industrial challenges:

- The rising need for flexible manufacturing systems, to support an increasing variety of product mixes.

- The need to maximise equipment utilisation rates, by eliminating down-time associated with changing of laser, processing heads and equipment stoppages and reducing capital investment costs.

An overview of the results and their exploitation plan are presented below:

- The ModuLase system was successfully demonstrated to an industrial audience on three industrial case study applications, covering welding, cutting and cladding processes; and proving the concept of the system for flexible manufacturing. The ModuLase full system is planned to be sold by SODECIA/GTAC.

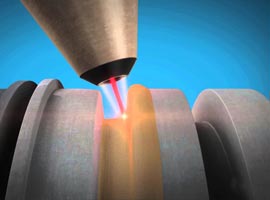

- A Beam Forming Unit (BFU), capable of delivering a wide-range of laser beam energy distributions (suitable for laser welding, cutting and cladding processes), was designed and manufactured. ULO will provide SODECIA with optics or optical sub-assemblies;

- Modular ‘plug and play’ end-effectors were designed and manufactured, which can be rapidly (less than 1 minute changeover) attached to the BFU to provide the additional functionality required for the different processes (welding, cladding and cutting processes). SODECIA will produce the Plug and play end-effectors in order to be assembled in the full system; and/or sell the end-effectors alone to integrate in other commercially available heads;

- A quality assurance system compatible with all three processes: welding, cladding and cutting processes, by using a VIS/NIR sensor (visible and near infrared spectral range) and a SWIR/MWIR sensor (short and mid wavelength infrared) coaxial to the laser process. Currently commercially available systems for Quality Assurance and Quality Control are process specific. Despite using similar technologies, existing process monitoring systems are typically supplied for one process. AIMEN will provide the Quality Monitoring system that could be integrated in the ModuLase head or in other commercially available heads;

- A friendly knowledge database was created and integrated within the Control-User interface, enabling ease use of laser technology for laser processing, without the need for expert knowledge in laser processing. Q-Sys will provide SODECIA with the User machine Interface in order to be assembled in the full system;

- Training: Harmonised system of qualification across Europe through EWF authorised training centres ;

- Know-how for development and adaption of laser processes and user-friendly HMI interface in the context of the overall ModuLase system: Industrial members of TWI, in Europe and worldwide, will benefit from the generated knowledge, which will find applications within the transport, power and aerospace sector as well as other industry sectors involving high variety/high volume manufacturing.

Dissemination material and activities were carried out to raise awareness about the ModuLase project among various target users and for attracting potential customers. Dissemination channels have included the project website, conferences, publications, the partners' own websites, training to an industrial audience, social-media channels. More details on publicly available dissemination material can be found on the ModuLase website here.

Activities for maximising exploitation of project results and reducing time to market were performed. Activities included an analysis on the potential market for the ModuLase technologies, potential commercialisation routes, Intellectual Property Rights (IPR) considerations and an evaluation of the ModuLase main competitors.

Potential impacts at the end of the project include the following areas:

– Process quality in line with project end-users requirements;

– Production overall time reduction: 20%;

– Equipment investment reduction: 40%;

– Shop Floor Utilization reduction: 40%.

Societal - By encouraging the uptake of laser processing by contract fabricators and Tier 1 and 2 manufacturers, a safe-guarding of existing jobs is expected, as well as the creation of highly skilled employment opportunities in the manufacturing sector within the EU. We estimate that ModuLase has the potential to increase employment opportunities by 8-12% within the consortium's end-users and supply chain (manufacturing the ModuLase system) by five years post-project. The majority of new jobs will be highly skilled engineers and researchers and will contribute to the development of a knowledge-based society. Furthermore, as laser welding does not require heavy manual labour, this social benefit should apply to workers regardless of their gender or age.

Environmental - While this project is environmentally neutral, laser processing is an energy efficient process compared with traditional materials processing techniques (~10% that of arc welding and cutting for example) and generates significantly less (~80%) fume. These will have localised environmental benefits for companies engaged in fabrication activities.

Today the ModuLase consortium met officially for the last time, in the Final Review Meeting with the EC.

This was a good journey, with its challenges, but that ended up culminating with the delivery of great and enthusiastic results!

We had the morning full of interesting information shared by the project partners, speakers of the event.

ModuLase consortium developed a processing head covering welding, cladding and cutting.

The system comprises of a monitoring unit, on board intelligent algorithms for setting the optical configuration and to help the user in the selection of process parameters. Adaptable optical elements capable of delivering a wide range of laser beam energy distributions, suitable for welding, cutting and cladding applications.

ModuLase internal training Session was hosted today, on-line, by EWF (but the preparation for this session was supported by all!). All partners participated and it was a good opportunity to transfer knowledge and experiences! It is good to see the benefits of a consortium with expertise at all different levels!